Today, purchasing is a strategic function and a key factor in competitive positioning; the role of the chief procurement officer is becoming as important as that of the CFO. Given purchasing’s strategic importance, one would think that good relationships between customers and suppliers are not unusual; in fact, they are elusive. People generally assume that it is the customer who does not trust the supplier, but surprisingly, suppliers are saying that they do not trust their customers. So it may take a world-class effort for customer companies to show suppliers that they are serious about partnering.

The Need for partnering

There is reason to be serious about partnering with suppliers. Corporations are becoming leaner. The procurement function is becoming more centralized while profit-and-loss (P&L.) responsibility becomes less centralized, which means that business-unit heads are raising more questions about the way things are bought. And as vertically integrated companies—those that have complete internal capabilities and are self-sufficient—become relies, more opportunities to partner with suppliers will arise. Taking advantage of these opportunities is increasingly important for several reasons:

Declining marker prices. Nobody expects prices to rise anymore. There is going to be a tighter squeeze on the margins of customer companies. They would like to get that margin reestablished by working with suppliers.

Rising competitive intensity. With the restructuring of the world economy, the formation of the World Trade Organization, and greater economic integration within and between regions, global consolidation is clearly taking place and resulting in greater competition.

Advanced technology enablers. Electronic commerce and networked computing are here. Dramatically reduced cycle times are becoming an ordinary achievement. These require working with suppliers.

Reverse marketing strategies. The traditional process flow—from R&D and sourcing to manufacturing, sales, and service—is becoming a thing of the past. Today, market- focused organizations are working backwards—starting with the end users. Partnering with suppliers is critical to this strategy.

Strategic positioning. In the past, we partnered primarily for operational efficiency (i.e., just-in-time procedures or zero-inventory models). Today, intense competition is coming from existing rivals, new entrants, and the threat of substitutes. Partnering with suppliers is an increasingly important way of minimizing the competition’s negative impact on an industry.

A Difficult Journey

Purchasing organizations have to be run smarter and better, status quo management will only lead to a downward drift. Unfortunately, companies tend to practice short-term status quo management Instead of practicing anticipatory management, which means looking at the procurement function not inside out bit from the outside in. Take a supplier perspective, and the world looks very different. Smart companies will learn how to elevate procurement to the next level of core competency, but this is floe an easy journey. They will have to overcome some formidable obstacles in order to successfully partner with suppliers.

Systems

For multiregional or multidomestic companies, one of the key bottlenecks in shifting front status quo management to anticipatory management is the lack of systems. These organizations have separate subsidiaries in several countries. They aspire to become integrated, global enterprises, but the information technology and accounting systems used in different countries may not be interoperable. Thus, rationalizing internally is a significant challenge.

Processes

Processes are not organized well. In the past, companies generally had a factory-to-market mindset and organized everything accordingly. Today, the mindset increasingly embraces reverse marketing—from market to factory. How to change the process flow to reflect the new mindset is a major challenge for purchasing.

Culture

The purchasing function has generally been administrative in nature; it needs to become more strategic and can do so only with the support of top management. Management can encourage purchasing to view the procurement function more strategically through compensation change and strong leadership. Nevertheless, culture is an internal challenge with which companies will have to struggle.

Supplier Resistance

Most suppliers do not trust customers and find that they are very opportunistic. Though the relationship may seem good at the front door, through the back door customers are always looking for alternatives. Suppliers tell us that customers are not ready to have relationships. Large global enterprises would like to have global sourcing from their suppliers and would like to have them invest all over the world at considerable risk, but most suppliers are not willing.

Customer Selectivity

Moreover, suppliers are for the first time practicing customer selectivity. Suppliers are identifying up front which customers will be profitable for them these customers are the ones with whom they want to partner. They are putting their best customers into key account management processes and leaving the rest. This will have a significant impact on purchasing departments. Retaining suppliers and creating loyalty among them are key reasons why organizations must treat suppliers the way they treat valued customers.

Partnering Enhancement Processes

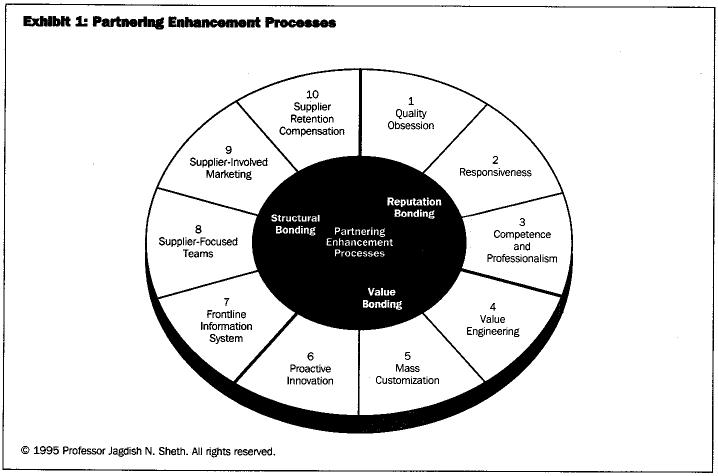

Partnering with key strategic suppliers requires a relations hip that transcends the sales and purchasing departments and is diffused throughout both organizations to involve information technology, cash-flow management, logistics, contracts, inventory, and so on. Enhancing the relationship with suppliers will require three different bonding processes:

reputation bonding, value bonding, and structural bonding (see Exhibit 1).

Reputation Bonding

Do you have integrity as a customer, and how can you improve trust? Is there a total quality process that enables things to be done right the first time? Are you courteous and responsive when your suppliers call, or do you keep them waiting? What is the degree of competence and professionalism of the people managing your suppliers? These factors contribute to your reputation.

Value Bonding

How do you create value for your suppliers? The process of value engineering provides the answer. Create economic value for your suppliers by eliminating redundancy and inefficiency and by reducing the cost of doing business. Supplier automation and the zero-inventory process are examples of enhancing economic value.

Another aspect of value bonding is mass customization— the standardization of customized orders through modular and flexible purchasing. A standard purchasing platform that allows for customized product orders and customized time-and-place orders can be generated by a demand-driven supply function.

Most innovations begin in the customer organization, not the supplier organization. Therefore, the customer can create economic value for the supplier by codeveloping new products and processes in anticipation of a future end use. Examining demographic trends and partnering intern ally with sales and marketing are ways of anticipating the future; relaying this information back to the supplier community is a way of creating value for them.

Structural Bonding

Frontline information systems, which include computerized reservation systems and electronic data interchange technologies, are one form of structural bonding. Supplier- focused teams are another form. As companies reduce the number of suppliers and begin to partner with a few key suppliers, they will have to reorganize the purchasing function into teams that focus on the key suppliers and the critical supply of products. Global sourcing and one-stop contacts are examples of outcomes.

It is also important to encourage supplier-involved marketing—the active involvement of suppliers in product design and process improvement through feedback communication, and participation. Suppliers should also be bragging about you if you are a good customer. Privately and informally, however, most suppliers do not speak highly of their customers.

But compensation change and leadership may be the most important method of structural bonding. We make sure that suppliers are happy with us through reward and recognition systems that are anchored so supplier retention and loyalty. If you are serious about partnering with suppliers and would like to transform your purchasing department, you must energize the department by having leadership that motivates and communicates effectively. Most organizations bring in a procurement leader who talks through, but they also need a reward system that is equally firm. Otherwise, nothing much happens.